Air dosing unit

Sulphur in biogas causes problems during combustion in the CHP. Desulphurization is useful. Using an air dosing unit it is possible to feed small amounts of oxygen into the digester tank.

Desulphurization of biogas takes place within the digester through the activity of naturally occurring bacteria that use the hydrogen sulphide in their metabolism and deposit elemental sulphur. They need a small amount of oxygen. To this end an air pump blows a small amount of air into the gas space in the digester. The amount of air should be about 4-6% of the amount of gas produced.

The full effect of desulphurization is attained after several weeks, when a gas biofilm of hydrogen sulfide consuming bacteria is formed on the surfaces. This is facilitated by higher temperatures, wetting the surfaces with slurry/substrate by rough surfaces.

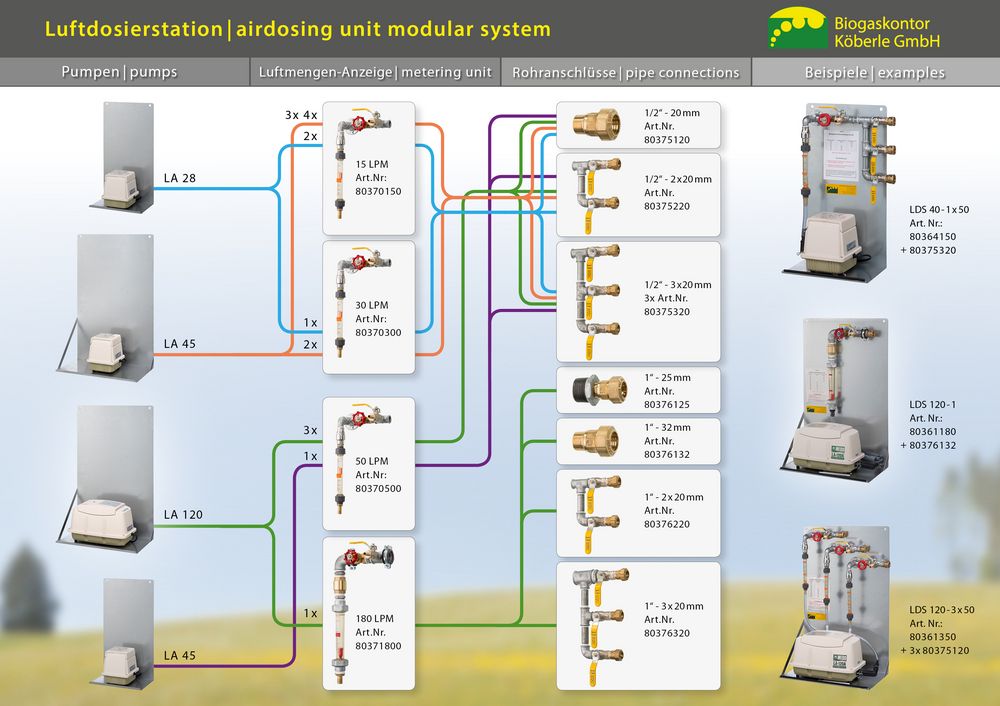

Part of the air dosing unit

Air pump for continuous operation

Air flowmeter device

Throttling valve to regulate the volume

Connection with ball valve for condensate drainage and pipe rinsing

Air nozzle with non-return valve

Dimensions

Type 20 for amounts of air up to 20 l/min

Type 40 for air amounts up to 40 l/min

Type 120 for air amounts up to 120 l/min

The indicated air quantities apply for pressure drop in the air pipes to the air nozzles of max 10 mbar and gas pressure maximum of 10 mbar in the digester.